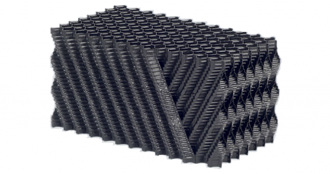

More efficient cooling by replacing cooling packing

An oil refinery from the Port of Antwerp asked us if it would be possible to adapt their counterflow cooling tower with axial suction fans so it could still cool the same water flow rate, but to a lower cold water temperature. The cooling tower consists of six cells.

The drive gear – motor + fan – had to be maintained with preferably no modifications to the structure of the cooling tower. Water distribution is OK.

The cooling tower is for the cooling of clean water.

The original design of the cooling tower was for a water flow rate of 13,890m³/hour to be cooled from 39.6°C to 26.1°C at a wet bulb temperature of 19.4°C.

We made various calculations and saw that with the replacement of the old cooling packing by new high efficiency cooling packing we could cool the same water flow rate of 13,890 m³/hour from 39.6°C to 24.8°C at the same wet bulb temperature of 19.4°C.

The power consumption of the fan will be slightly higher, but still within the capabilities of the existing 160 K motors.

This results in an increase in the cooling capacity from 218 MW to 239 MW, but still with a perceptible improvement for a lower cold water temperature. The combination of a higher discharged cooling capacity and at a lower cold water temperature offers enormous opportunities of a higher production capacity for the refinery with a negligible cost recovery time.

One cell was initially tackled, and after carrying out thorough performance measurements the cooling packing was also replaced in the other five cells.