Replacement of the fan of a Polacel cooling tower

We were asked by a Rotterdam vegetable oil refinery to replace a fan of a Polacel cooling tower. The existing fan was a 14-foot fan with aluminium blades.

Conditions set by the customer:

- It must be an Atex fan. (zone II 2G, T1-T6)

- It must be more efficient than the existing fan.

- It must be quieter than the existing fan.

- Account must be taken of the fans of the other existing cooling towers to keep as few as possible replacement parts in stock.

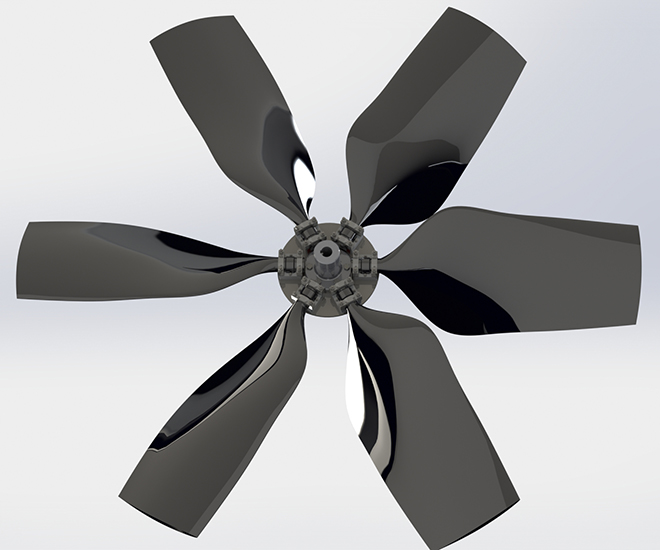

Almeco supplied and installed a 14-foot Atex fan with the following properties:

| Diameter of the impeller | 14 feet |

| Number of blades | 6 |

| Speed | 227 rpm |

| Execution | Atex (zone II 2G, T1-T6) |

| Blades | Glass fibre-reinforced polyester - anti-static - self-extinguishing |

| Clamp block/clamping ring | Hot-dip galvanised/steel |

| Hub disk | Hot-dip galvanised |

| Hub | Steel with special antistatic coating |

| Bolts and nuts | Hot-dip galvanised (A2 possible without surcharge) |

Work carried out by Almeco:

- Complete maintenance of the cooling tower

- Disassembly of the existing drive gear

- Replacement of the gearbox with an overhauled gearbox supplied by the customer

- Installation of new drive shaft and alignment of this shaft

- Installation of fan supplied by Almeco

- Vibration checks on the installed fan for control purposes (balancing was not necessary)

The cooling tower with the new fan is now operational again.