THE AMR 26, the newest addition to our FANily

THE AMR 26, the newest addition to our FANily

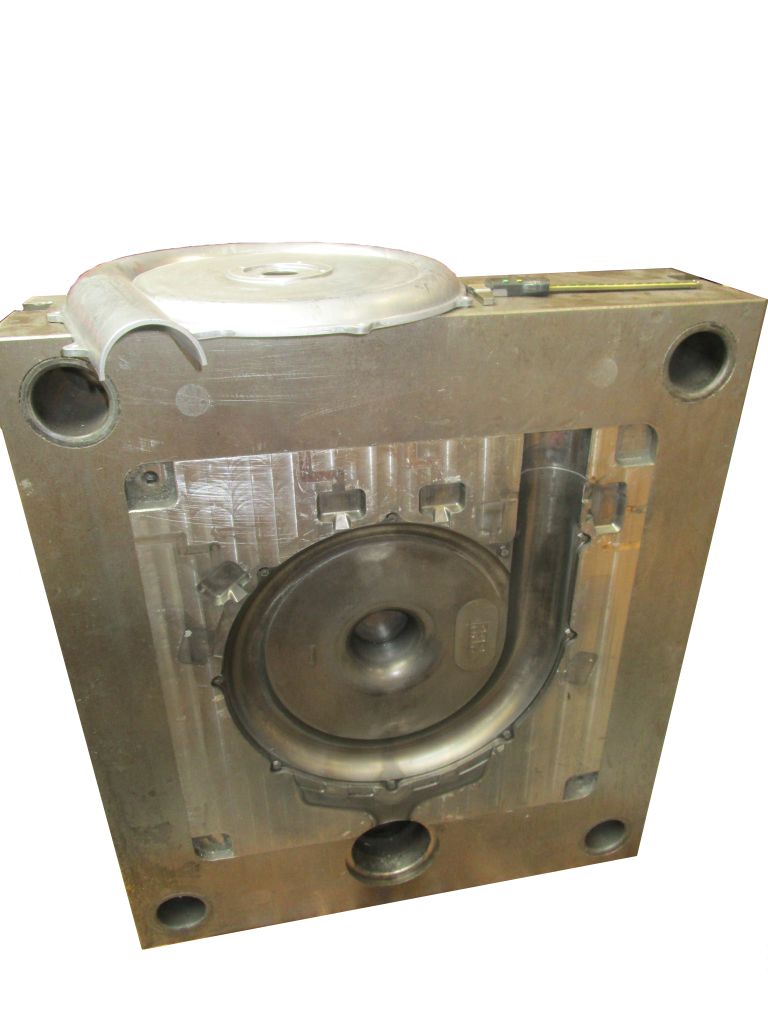

Recently, we started designing our own centrifugal fans. Our engineers draw the designs in 3D using their extensive expertise. Since we don’t have the infrastructure to cast aluminium, we call upon a local partner. Based on their knowledge and experience, we chose to use the injection molding process. Therefore they made massive moulds in a specific steel which guarantees a tool life of more than 100.000 pieces. This injection molding process also guarantees an increased efficiency, a decreased cost per piece, and offers the possibility to cast the aluminium thinner and stronger. These aluminium casts are assembled with various kinds of motors in our workshop in Moeskroen. Before we send the fans to our clients, they have to undergo an extensive quality check.

The method of this project was something we hadn’t done before. But this first experience certainly met our expectations. It wasn’t only a good move economically speaking, but also strategically. After all, we are now less dependent on our suppliers than before.

Do you need a custom made aluminium centrifugal fan, don’t hesitate to call upon our expertise!