Cooling towers with open, closed or hybrid cooling circuit

Cooling towers with open, closed or hybrid cooling circuit

Almeco’s cooling tower range includes open, closed and hybrid circuit cooling towers (adiabatic cooling towers).

Open circuit cooling towers

In open circuit cooling towers, there is a direct contact between the water to cool down and the air.

An open cooling tower is a heat exchanger that in order to cool down water makes use of the direct contact with the air. The heat transfer occurs partially thanks to a heat exchange between air and water, but mainly thanks to the evaporation of a small quantity of the water that needs to be cooled. This will allow to cool down to a temperature lower than the ambient temperature.

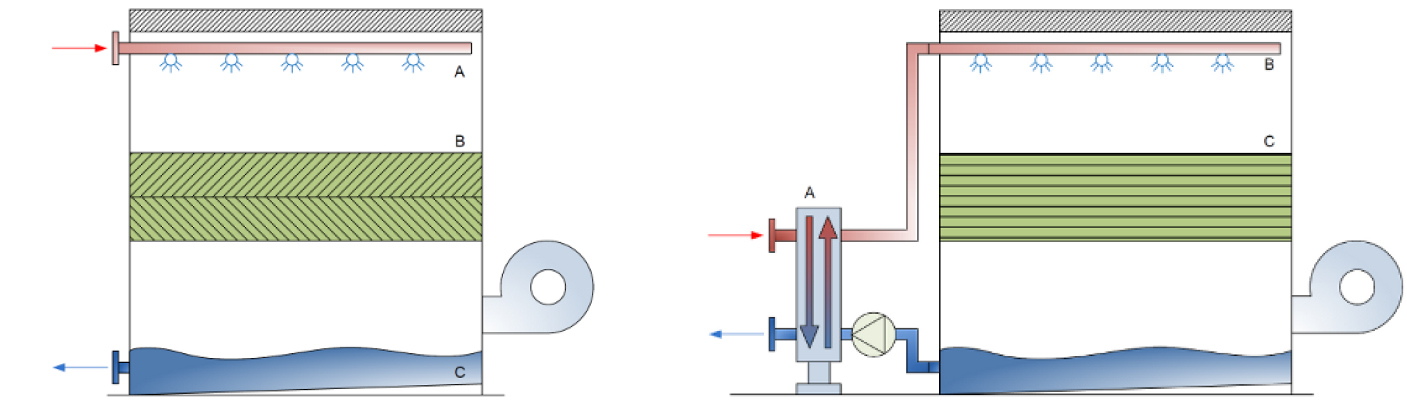

Operation

- The water that needs to be cooled will be directed to the upper part of the cooling tower.

- The nozzles (A) distribute water over the tower packing (B).

- Water will be spread in a thin and even film over the packing thanks to its shape. This will result in a very large contact surface (heat exchange surface).

- The fan blows or extracts (depending on the type of fan) ambient air through the packing. This air will cool the water in 2 different ways. Part of the heat will be removed due to convection (contact between hot water and colder air), but the main cooling part will be because of evaporation.

- The air, which is now saturated with humidity, will be exhausted through the upper part.

- The cooled down water will be gathered in the basin (C) so it can be reused in the production process.

- The drop eliminators above the nozzles make sure that the water drops don't leave the cooling tower.

Closed circuit cooling towers

There is no direct contact between the water to cool down and the air inside closed circuit cooling towers, but an additional heat exchanger is however used. Cooling towers with piping and plate heat exchanger also exist.

A cooling tower is a heat exchanger that uses the direct contact with the air to cool down water. The heat exchange happens partially through a heat exchange between air and water, but mainly through the evaporation of a small quantity of the water that needs to be cooled. This will allow to cool down to a temperature lower than the ambient temperature.

When the water that needs to be cooled cannot get into contact with the air (e.g. in the food industry), it is necessary to use a heat exchanger.

The heat exchanger separates the process water that needs te be cooled from the “evaporation water” of the cooling tower. This will avoid contact between the process water and the air.

In open circuit cooling towers it is not necessary to use anti-freeze, the use of anti-freeze in the closed cooling towers might be necessary.

Process side

- The process water that needs to be cooled will be guided through the heat exchanger (A). This heat exchanger consists of stainless steel plates and is situated next to the cooling tower in a separate adjacent room.

- Inside the heat exchanger, the heat of the water from the process side is transmitted to the cooling water on the cooling tower side.

- The process water is now cooled down again and can be reused as cooling water in the process. Consequently, the cooling water circulates in a closed circuit between the consumers (production machines, condensers, etc.) and the heat exchanger.

Cooling tower side

- Once the reheated cooling water has left the plate heat exchanger, it will be directed through the piping to the upper part of the cooling tower, where nozzles (B) will distribute the water over the tower packing (C).

- The cooled down water falls through the packing and is gathered in the basin. This is where the fresh water will be led back through the recirculation pump (D) to the heat exchanger in order to be reused.

- The water is cooled down by the air which is developed by the fan(s) in counter flow. This air will warm up and get saturated after contact with the water flowing over the packing. The air is exhausted through the top.

- The drop eliminators above the nozzles make sure that the water drops don't leave the cooling tower.

Adiabatic cooler (hybrid cooling circuit)

An adiabatic cooler is a liquid cooler. The heat to be removed is discharged dry throughout most of the year by only using the ambient air. As soon as the temperature of the ambient air becomes too high, this will appliance will automatically switch over to wet mode and make additional use of the cooling effect of evaporating water.

Our blog post 'How does an adiabatic cooler work?' includes more information about the working of this type of cooler.