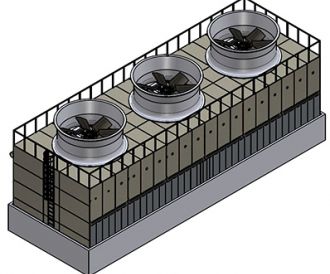

Cooling towers play an important part in many industrial processes. If these cooling towers no longer maintain their cooling capacity, this obviously has far-reaching consequences for your production process. A reduction of the cooling capacity often has the same cause: a soiled cooling tower.

The importance of cooling tower maintenance

A soiled cooling tower is nonetheless very simple to avoid: by regular, preferably annual, preventive maintenance. Regular maintenance of your cooling tower indeed ensures that:

- The operating reliability of your cooling tower remains optimal

- Your cooling tower continues to operate as it should

- Your cooling tower retains its cooling capacity

- The risk of Legionella’s disease is minimised

- The working life of your cooling tower is extended (so you do not have to replace your cooling tower so soon)

- Unnecessarily premature wear of your cooling tower is avoided

It is obviously best to have maintenance carried out by specialised technicians with the use of parts suitable for the cooling tower and the cooling process. These do not have to be original parts from the cooling tower manufacturer by definition. High quality replacement parts provide just as good – and sometimes even better – performance than the original parts.

Trust in an experienced partner

Almeco complements a complete range of new construction cooling towers, replacement parts and options in the field of water treatment with years of experience in the field of cooling tower maintenance. You can accordingly call upon us for the maintenance of cooling towers of all makes and all types. We also have much experience in the revamping of crossflow cooling towers. Almeco is also in possession of the VCA** certificate.

Almeco carries out predictive, preventive and curative activities.

Research and analysis

- General analysis of the complete cooling tower

- Tracing of weaknesses

- Scheduled maintenance to prevent unscheduled production fall-out

Mechanical repairs

- Fan (including balancing, alignment, vibration investigation, etc.)

- Drive gear (motor, gearboxes, belt drives, bearings, etc.)

Supervision, cleaning or replacement of parts

- Packing and drift separators

- Water distribution

- Fan system

- ...

Upgrading the cooling tower

- Increasing capacity

- Adaptations in line with environmental standards (for example noise)